WebPro® Series

Preco, Inc. integrates advanced laser technology with reliable equipment, offering innovative and cost-effective solutions for web-based laser cutting, scoring, slitting and kiss-cutting. Our WebPro series of digital laser cutting systems are available in narrow or wide web formats with single or multiple lasers. We offer a variety of roll handling, laser processing and robotic stacking options with each platform to meet your abrasive product manufacturing needs.

The WebPro Series of digital laser cutting systems are rapidly reconfigured for changing job requirements and are the ideal match for short run jobs in all sizes and materials. The AcuBeam™ control system operates in a user-friendly Windows® environment, allowing you to control the entire system from a single interface. As a result, changeovers are as simple as opening a file without the need or costs of tooling!

WebPro LB3000

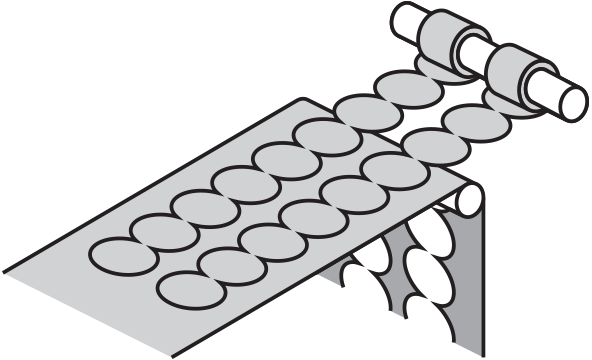

Preco's WebPro LB3000 series are narrow web-based laser systems for roll-to-roll or roll-to-discrete part processing.

WebPro LB3500

Preco's WebPro LB3500 series are wide web-based, traveling head laser systems for roll-to-roll or roll-to-discrete part processing.

WebPro LB4000

Preco’s WebPro LB4000 series are wide web-based laser systems for roll-to-roll or roll-to-discrete part processing.

Laser Cutting

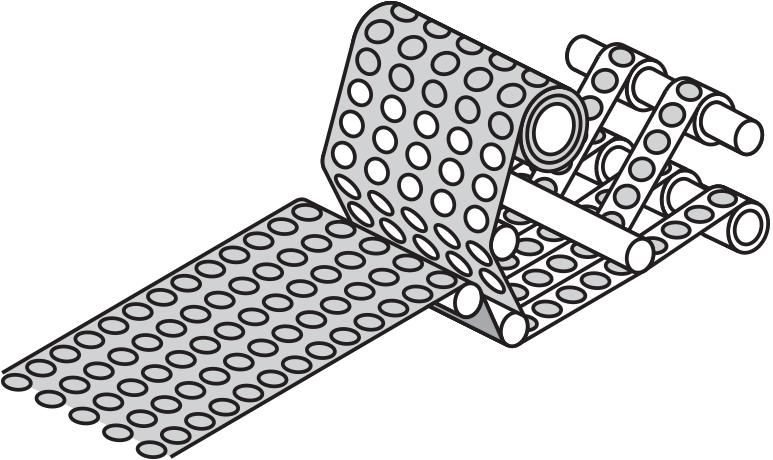

Laser cutting offers a unique alternative to conventional methods since lasers are a non-contact, clean process, with no dust or fraying. Laser cut parts are virtually chad-free. The laser beam is always sharp resulting in consistent, repeatable cuts with superior edge quality.

- Laser cutting is fully digital, direct cut from a CAD file

- Nearly instantaneous results – not waiting for tooling or set-up

- Small features and geometry

- Minimal distance between parts (maximizing yield)

- No delamination of multi-layered products

- Inventory reduction – make to order

- Product identification

Preco’s high speed, "cut on the fly" laser systems offer controls and accuracies that enable you to cut a variety of shapes and products. These systems cut 24 grit or higher and kiss cut 80 grit and finer, both with various backings (paper, polymer, cloth, fiber, hook & loop and adhesives) and can be either roll or sheet stock. Alternate wavelengths are available for polymer-based abrasives to minimize or eliminate edge burrs.

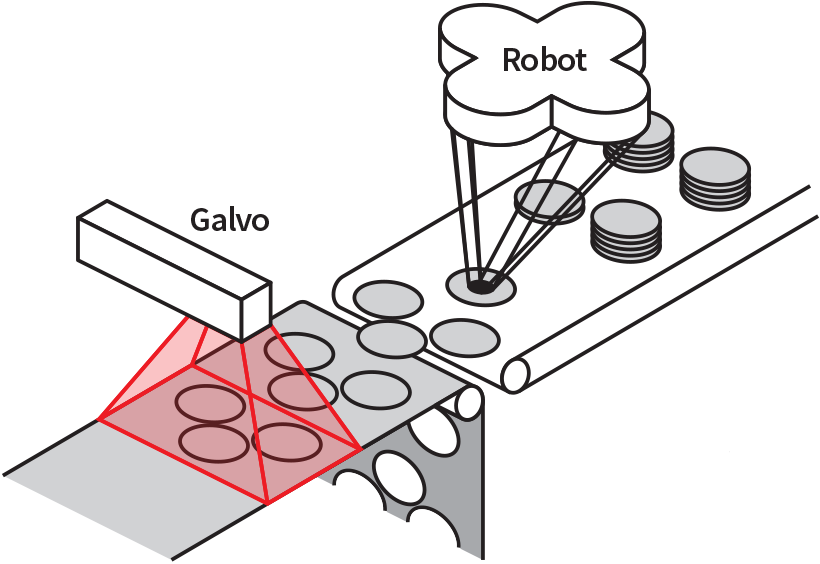

Custom Laser Systems

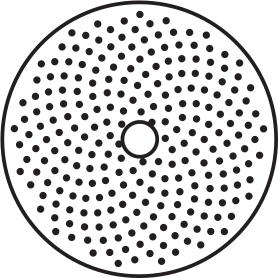

- High production systems offering multiple laser stations across a wide web

- Ideal for high-density dust free hole abrasive disc technology

- Proprietary laser cutting and disc handling techniques include robotic unload, counting, and stacking of discs

Estimated Throughput per Laser Power Level (Watts)

Disk Type |

Grit |

Discs Per Hour | |

| 1,000 W | 2,000 W | ||

6" disc without holes |

P80 | 3,500 | 4,700 |

| P150 | 5,000 | 6,000 | |

| P400 | 5,800 | 6,300 | |

6" disc with 7 holes |

P80 | 2,700 | 3,960 |

| P150 | 4,300 | 5,100 | |

| P400 | 5,100 | 5,700 | |

6" disc with 15 holes |

P80 | 2,300 | 3,300 |

| P150 | 3,700 | 4,500 | |

| P400 | 4,500 | 5,100 | |

6" multi-hole disc (100 - 400+ holes) |

P80 | 900 - 1,200 | 1,400 - 1,800 |

| P150 | 1,500 - 2,000 | 2,000 - 2,700 | |

| P400 | 2,000 - 2,700 | 2,300 - 3,100 | |

Have Questions? Contact Us