Equipment Manufacturing

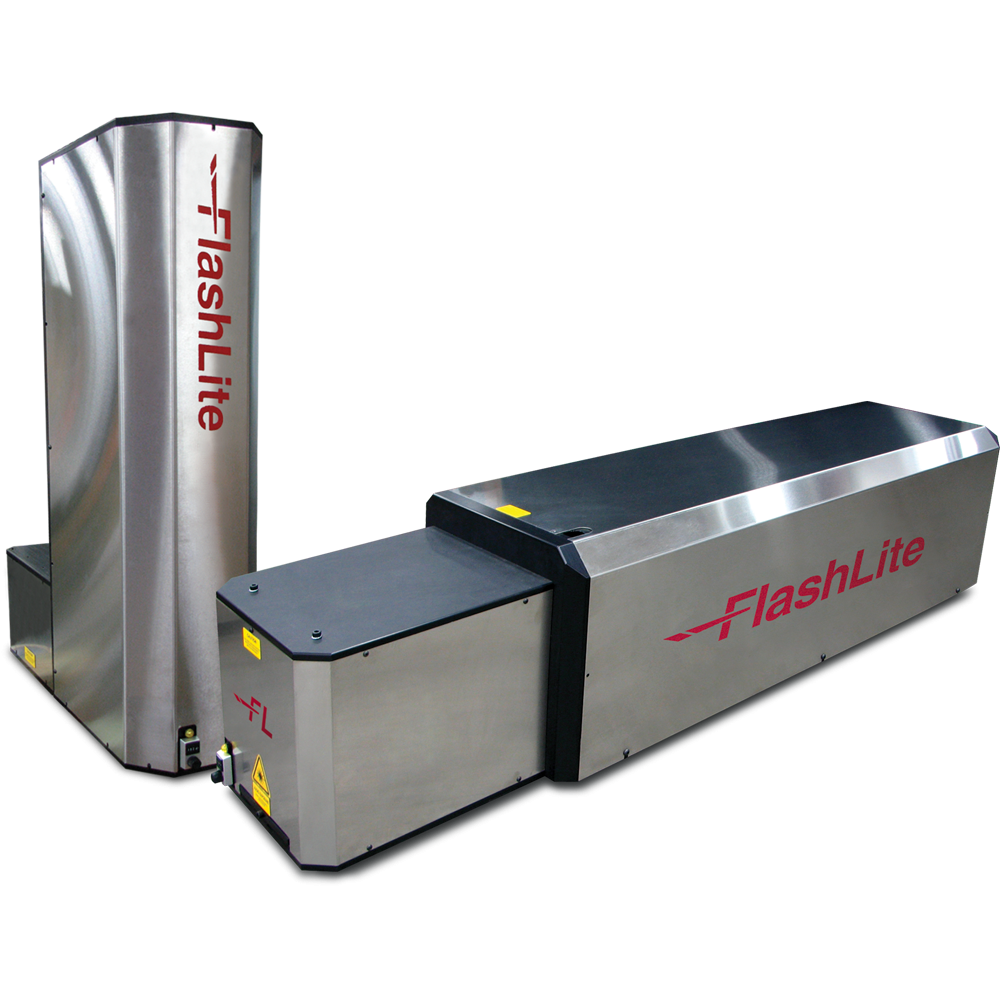

Laser Systems

ABOUT OUR LASER EQUIPMENT

Electronic devices have demanding constraints in terms of quality and often require challenging industrial manufacturing processes. For these reasons, laser processing offers unique advantages for expanding the markets capabilities. Laser processing meets the stringent requirement for clean edges free of loose particules. Preco, Inc offers standard and custom built laser systems to ablate, cut, drill, perforate, and score a variety of materials in either web or sheet form. Common applications are for via drilling, ablation of conductive layers / ITO, RFID trimming, clean cutting of screen protectors, EL/thin film displays, flexible circuits, membrane switches and spacers.

Flat Bed & Rotary Die Cutting Systems

Rotary Die Cutting Converting Platform

The need for the highest yields and production rates calls for die cutting that delivers flexibility and speed.

Flat Bed Die Cutter

The four post hydraulic press is our standard flat bed die cutting system and is available in a variety of platen size.

ABOUT OUR FLAT BED & ROTARY DIE CUTTING EQUIPMENT

Die Cutting in both flatbed web or sheet, and rotary web are well understood by Preco, and when either method is best for your material processing. Preco assists your company in choosing which equipment practice makes sense for profitable production for the project at hand, including finishing techniques that may be required for a successful outcome.