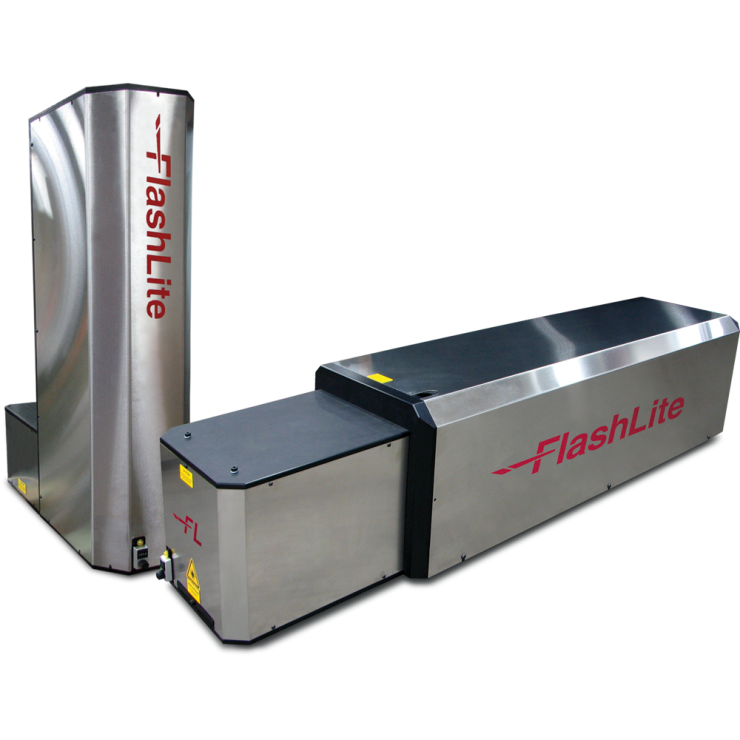

Compact Laser Processing Module

This compact and economical version of the Preco high-speed "directed beam" technology provides laser processing for numerous applications. Preco's FlashLite™ G series laser module is all you need if you already have material handling in place. This compact processing module is a cost-effective, complete laser package that can be added to virtually any web or sheet handling line. Laser processing is typically on the fly or in a step and repeat manner. Laser triggering is based on distance, eye mark triggering or vision registration.

Applications

- Advanced Wound Care: Dressings, plasters, bandages

- Body Sensors & Wearables

- Cosmetics – Hydrogel Face Masks

- Flexible Circuits (Hand held test devices)

- Food Safety Devices

- Microfluidics

- Point-of-care, diagnostic test strips

Standard Features

- Laser module with high speed directed beam technology

- AcuBeam® control software with CAD interface

- Patented AcuPower™ with ramp up/down power control

- Laser beam shutter for safe operation

Materials

- Acrylic Foam Adhesives

- Hydrogel

- Hydrocolloid

- Non-Wovens

- PET

- PLA

- PMMA

- PP, BOPP

- Pressure Sensitive Adhesives

- Silicone Adhesives

Capabilities

- Ablation

- Brand Marking

- Cutting

- Etching

- Kiss-cutting

- Perforating

- Scoring / Scribing

- Via Drilling (Micro-via)

Features & Benefits

Small footprint allows module to be used virtually anywhere - from prototyping labs to production facilities

Provides uniform scoring independent of shape and processing speeds

Reduces set-up time; consistent production from operator to operator

Increased margins; High through-put and low operating cost

Eliminates inconsistencies of knives and other mechanical methodsSave

Easy to use Windows® based software enable make-to-order processing of short-run or complex jobs

I/O available for seamless interface to existing production line or material handler

Allows for optimized cut speed and cut quality from one job to the next

Precision control of laser energy, unique to Preco (Optional)

Technical Parameters

Laser Specifications

| Model | FL-G 100 | FL-G 200 | FL-G 300 | FL-G 400 | ||||||||

| Laser Wavelength (μm) | 9.4 | 10.2 | 10.6 | 9.4 | 10.2 | 10.6 | 9.4 | 10.2 | 10.6 | 9.4 | 10.2 | 10.6 |

| CW Power Range (rated W) | 5-80 | 5-100 | 5-100 | 5-150 | 5-160 | 5-200 | 10-225 | 10-240 | 10-300 | 40-400 | ||

| % Power Stability* | < ± 2 - 5 | < ± 5 - 7 | < ± 5 - 7 | < ± 5 - 7 | ||||||||

| Chiller Requirements | 2-kW, 7.5-l/min @20 °C | 5-kW, 6-l/min @20 °C | 7-kW, 6-l/min @20 °C | 8-kW, 7-l/min @ 20 °C | ||||||||

Environmental Requirements

| Model | FL-G 100 | FL-G 200 | FL-G 300 | FL-G 400 |

| Temperature | 18 - 27° C (65 - 80° F) | |||

| Altitude | 2,000 meters (1.2 miles) | |||

| Humidity | < 95% non-condensing | |||

Electrical Requirements

| Model | FL-G 100 | FL-G 200 | FL-G 300 | FL-G 400 |

| Voltage / Phase / Hertz | 200 - 230 VAC, 1 Phase, 50/60 Hz | 200 - 230 VAC, 1 or 3 Phase, 50/60 Hz | US: 200 - 230 VAC, 3 Phase, 60 Hz Int: 380 - 420 VAC, 3 Phase, 50 Hz |

US: 200 - 230 VAC, 3 Phase, 60 Hz Int: 380 - 420 VAC, 3 Phase, 50 Hz |

Have Questions? Contact Us