Designed for Precision Laser Cut Tube Processing

The Preco RT1000 is designed for precision laser cutting small diameter tubes for medical devices such as surgical

instruments, stents and other implantable devices. The combination of a granite base, precision servo drives, rigid work holding, fiber delivered laser sources and Preco's optimized fine cutting head offers unmatched precision and productivity.

Features & Benefits

An isolated rigid and stable base provides superior part accuracy and quality of cut.

A well designed enclosure provides excellent part access during set-up and maintenance, while providing CDRH Class I protection during operation.

As standard, this system has a single mode fiber delivered laser. Additional laser sources can be integrated to meet specific customer requirements.

The Preco fine cutting head was designed and built specifically for thin wall laser cutting with a clean edge and minimal thermal input. The head utilizes three focusing lenses and power modulation to minimize the damaging effects of tube backwall laser strikes.

The tube periphery cutting is controlled by a linear motor X axis and a brushless direct drive servo motor for the rotary axis. The accuracy for the X axis is +/- 7 microns and +/- 50 arc-seconds for the rotary axis.

The YZ stage is ball screw driven incorporating brushless servo motors with accuracies of +/- 5 microns for the Y axis and +/- 20 micron for the Z axis. The programmable Y and Z axis motion produces parallel wall features while off axis cutting.

An integrated water pump can be used in applications where water cooling of the tube is required.

Preco's PC based machine HMI is a CNC controller designed for laser processing with G-code programming.

Options

LASER OPTIONS

To optimize your specific application (metallic or polymer tubes), fiber delivered continuous wave or pulsed lasers along with CO² lasers can be integrated to the RT1000.

MANUAL ADJUST Y AND Z AXIS

In lieu of servo control axes, the stages can be controlled manually if off-axis processing is not required.

AUTOMATED TUBE FEEDER

For high volume unattended operation, an automated tube feeder with magazine loader can be integrated to the RT1000.

Technical Parameters

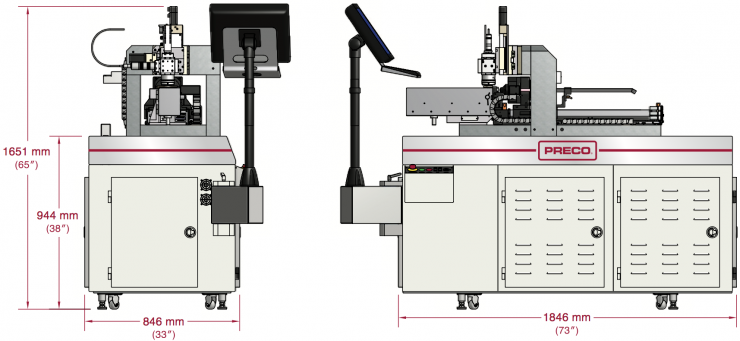

| System Footprint | Width: 1846 mm (73 in) | |

| Depth: 846 mm (33 in) | ||

| Height: 1651 mm (65 in) | ||

| Safety Enclosure | Class 1 | |

Have Questions? Contact Us