Equipment Manufacturing

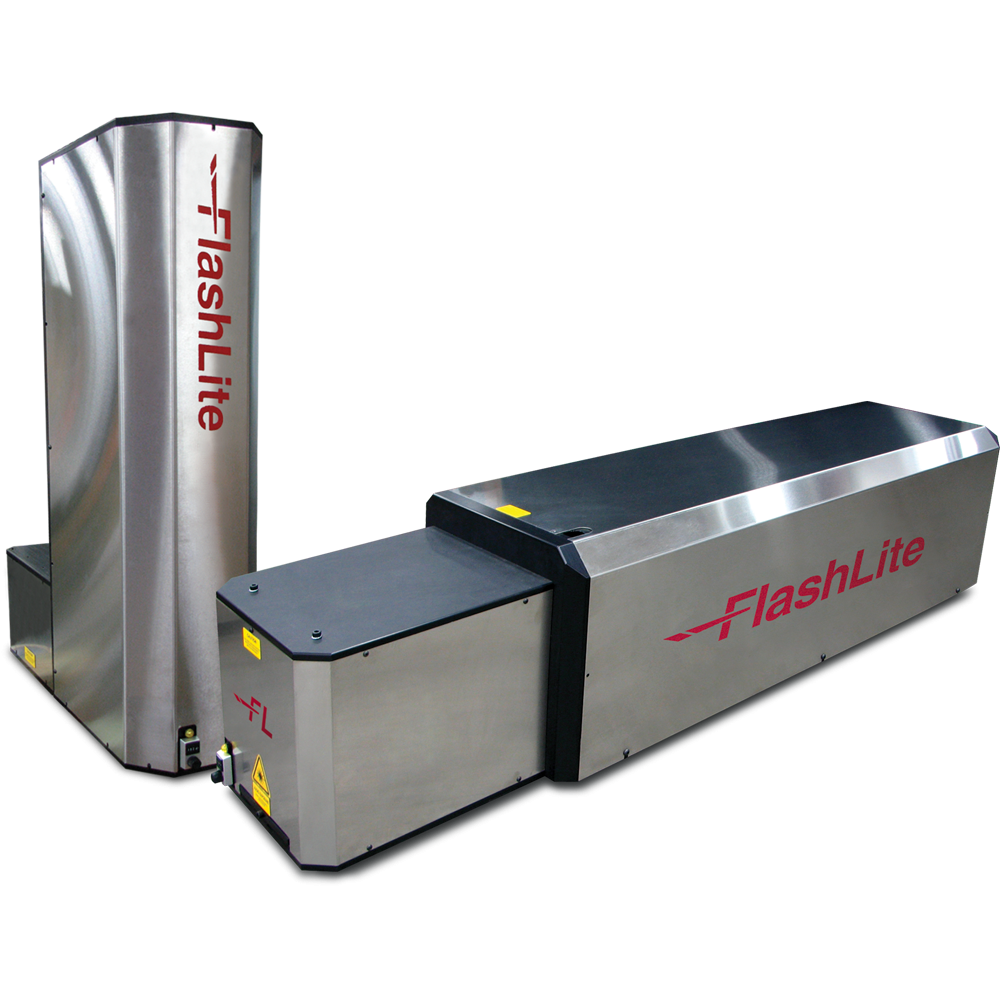

Laser Systems

ABOUT OUR LASER EQUIPMENT

Medical devices have demanding constraints in terms of quality and often require challenging industrial manufacturing processes. For these reasons, laser processing is gaining significant growth in medical device manufacturing. Laser processing fulfills the quality requirements for perfectly clean and hygienic surfaces, free of any material residue. Preco, Inc. offers standard and custom built laser systems to cut, weld, score and ablate a wide variety of films, textiles, metal and plastic medical components used for microfluidics, wound care, patient monitoring, wearable sensors, surgical tools and implant devices such as stents and catheter guide wires.

Flat Bed & Rotary Die Cutting Systems

ABOUT OUR FLAT BED & ROTARY DIE CUTTING EQUIPMENT

Converters need versatility and precision to handle the wide variety of products to meet specific requirements and guidelines for medical products. Preco, a premier supplier of flat bed and rotary die cutting equipment, understands and meets these processing needs. In addition, rotary die cutting is a great option to produce complex laminated medical products.