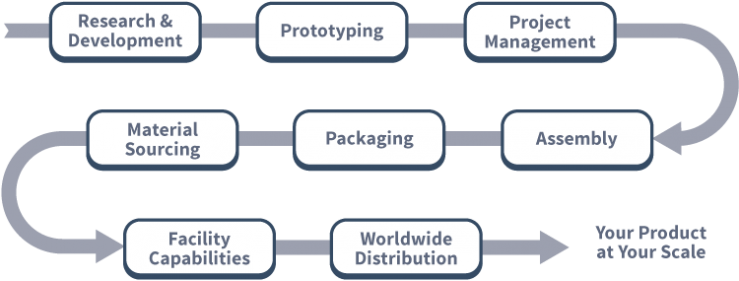

Preco's experience, technology and innovation drive our engineering and product processing capabilities. By partnering with us you are able to tap into our manufacturing expertise to reduce costs and improve efficiency when bringing your product to market. Though every industry and project presents its own unique challenges and design needs, our broad range of experience allows us to tailor a creative solution to your product requirements. At Preco, Inc. we don’t just provide multiple services, we deliver a complete solution.

Project Management

With a dedicated project management team with decades of experience, we are able to make a smooth transition from prototype to mass production. One of our project management engineers will lead your project every step of the way. Creating and maintaining a well-documented process development timeline ensures your project stays on track to commercialization.

Material Sourcing

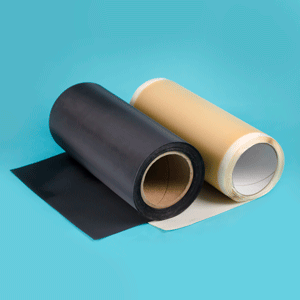

We have been building supplier relationships for over 40 years. We take into account your product’s specifications and performance requirements, and combine with our vast knowledge of metallurgy, polymers, and composites to offer you the optimum materials to choose from. In the event you need a custom material manufactured for your product, we will facilitate the development by providing laser, rotary, or die cut samples for your review and testing as the material is developed. Given our wide array of machines and laser wavelengths available, we are able to process many unique materials with much less scrap than traditional processing methods. Some benefits of laser processing include minimized distortion and heat affected zone (HAZ), clean edges, low scrap rate, and complex profiles or geometries.

Prototyping

Preco’s applications engineering team helps our customers through the product development cycle with quick turn samples and mockups. Many times if a small quantity is required, we can do so with minimal or no special tooling, saving the customer both time and money.

Prototyping Features

- Alternative raw materials if there are long lead time constraints

- Having complete prototypes finished and ready for use in as little as 2 days

- Electronic exchange of drawings and specs eliminates non-value added delays

- Inspection information emailed to you before your parts ship

Facility Capabilities

- Laser based manufacturing

- Flat Bed Die Cutting

- Rotary Die Cutting with integrated laser processing inline

- Fiber and C02 based lasers

- Infrared, Visible, Ultraviolet laser wavelengths for optimum processing

- Femtosecond laser pulsing capabilities

- Full metallographic inspection processes

- Machine Vision Inspection Systems

- Robotic part handling

- Industrial Parts Washers

- Industrial Heat Treat ovens

Assembly

Preco has become a total solution provider to our customers by managing the complete supply chain, inventorying all raw materials, and assembling and packaging our customers’ products so they are ready for distribution to end markets.

Worldwide Distribution

Preco currently ships products worldwide, including North and South America, Asia, and throughout Europe. Our experience shipping overseas and handling all arrangements with our freight forwarding partners, means peace of mind for our customers. We know on time deliveries are critical and are proud of our continued excellence in this area.

Have Questions? Contact Us