Proven Performance

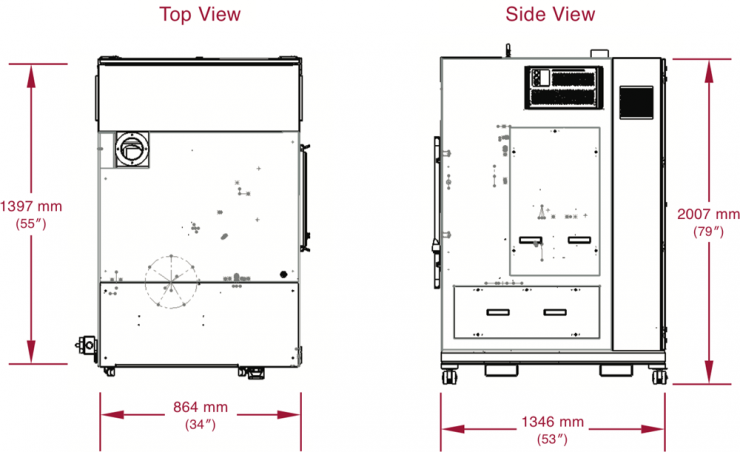

The Preco ST1000 Series laser workstation performs multi-axis laser welding, drilling and cutting in a class I enclosure. ST1000 Series workstations are time and field proven machines designed around fixed beam or fiber laser technology and Preco XY motion and control technology.

The rigid Preco design offers a smooth cutting path with high accuracy over the full range of motion and has high overall system reliability with a simple optical path and user friendly PC controls.

Applications

- Aerospace

- Automotive

- Telecommunications

- Medical

- Dental

- Electronics

- Welding of pump housings

- Ceramics for cutting tool applications

- Special sensors and transducers

Capabilities

- Cutting

- Drilling

- Welding

- Heat Treating

Features & Benefits

Laser ready - accepts most fiber delivered laser sources and hard optic lasers

Maximize consistency of processing accuracy and speed

Insures operator safety at all times

Superior pulse quality & control Nd:YAG or CO² lasers - Accepts 1.06 or 10.6 micron wavelength

Part presentation to outside of enclosure allows for manual, robotic, or overhead loading/unloading

User friendly, short learning curve and lower cost

Windows® based software with built-in ramping and power control - Save settings and shortcuts on production computer

Technical Parameters

| XY table with galvanometer | Larger sheets and part sizes to be cut with higher precision and better quality | |

| Automatic tiling | Saves programming time because large cut fields are automatically segmented to fit current field-of-view | |

| Fixed 2-axis scanhead | Optimized field-of-view for the fastest throughput | |

| Preco patented AcuPower™ | Provides uniform processing independent of cut shape and processing speeds | |

| Job database | Reduces set-up time; consistent production from operator to operator | |

| Automation choices | Rotary (1500 rpm) with ER-16 collet 25 mm lift stage - adjust material height under scan head or fixed beam | |

| Pneumatic exhaust gate | Programmable vacuum control during load and unload process | |

| Laser choices | Configured to accept various laser wavelengths and power based on material to be processed | |

| XY table wth fixed beam or fiber delivered | Allows intricate processing in sheet or rotary form | |

Have Questions? Contact Us