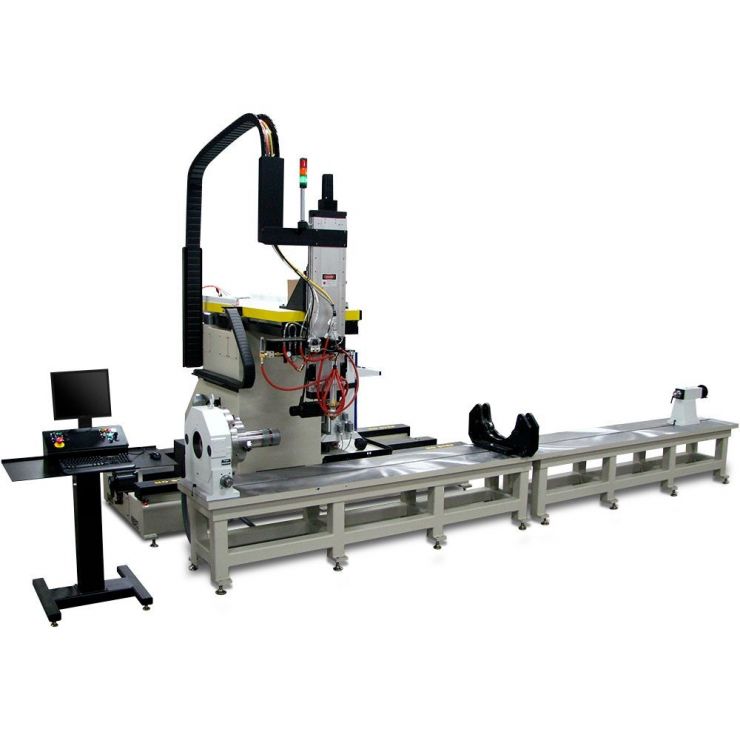

Laser Cladding Solutions

Preco manufactures systems for the deposition of powder metal or wire onto a base metal (part) to metallurgical bond the dissimilar materials. Preco cladding systems can be used for round or flat parts up to 30 meters standard (larger on request). We offer both Cartesian platforms or robotic based systems. Laser cladding increases the life span for components by improving corrosion and wear properties. Laser cladding can be precisely placed with minimal heat input and distortion. The laser clad has low porosity and a fine microstructure. Automotive components, tools in the oil and gas industry, cylinders for mining, and tool and die all benefit from the wear protection provided by this process.

What is Laser Cladding?

Laser cladding is the disposition of material in the form of a powder or wire onto a substrate with a metallurgical bond, while minimizing dilution and the heat-affected zone.

Laser Clads increase the lifespan of equipment by renewing the surface, or improving its corrosion and wear properties.

Applications

- Tool and Die

- Valves and Seals

- Turbine Blades

- Drive Shafts

- Automotive Components

- Cylinders for Mining

Materials

- Stainless Steel

- Carbon Steel

- Alloy Steel

- Nickel Based Alloys

- Cobalt Based Alloys

- Hard Particle Composites

Have Questions? Contact Us