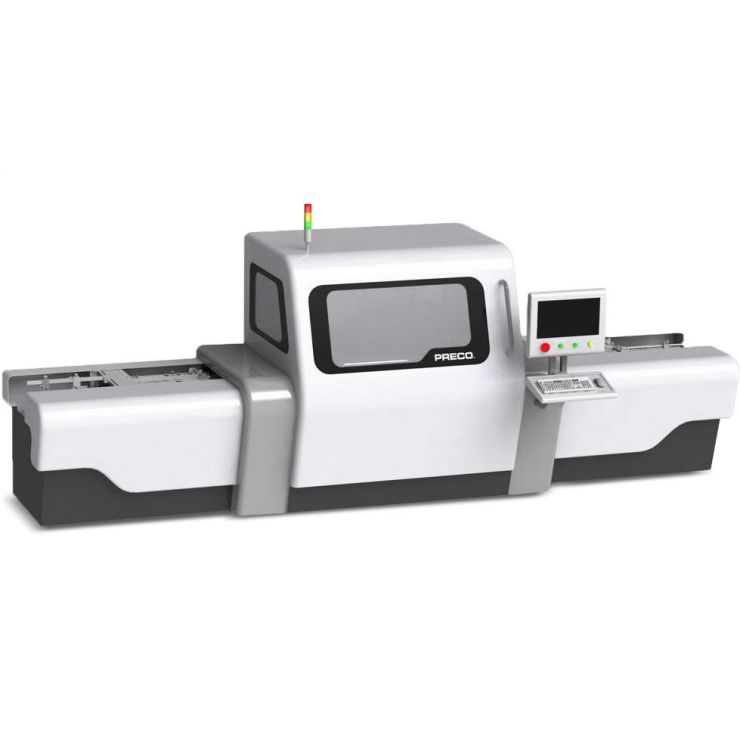

Innovative and Cost-Effective

Preco, Inc. integrates advanced laser technology with reliable equipment, offering innovative and cost-effective solutions for sheet-based laser cutting, etching, perforating, kiss-cutting/scoring.

The FlexStar Series of digital laser cutting systems are rapidly re-configured for changing job requirements and are the ideal match for short run jobs in all sizes and materials. The AcuBeamTM control system operates in a user friendly Windows® environment, allowing you to control the entire system. As a result, changeovers are as simple as opening a file without the need or costs of tooling!

This unique system allows you to process sheet widths from 300 mm (12 in) to 500 mm (20 in) at high production rates. Our proprietary conveyor system transports the sheets through the processing area to a manual or (optional) automated unload station.

The FlexStar Series Laser System incorporates 200, 300 or 400 watt CO2 lasers. These lasers offer a reliable, precise beam that results in clean and sharp laser processed edges. In conjunction with our patented AcuPowerTM sub system which is interfaced through our AcuBeamTM control software, and adjusts laser power "on-the-fly" based on the beam movements. This technology simplifies the set-up process for cutting, provides greater control of laser power to avoid burn-through during kiss cutting/scoring and provides precision in complicated shape cutting.

Applications

- Folding carton

- Direct mail

- Table tents

- Business cards

- Point-of-purchase

- Greeting/Holiday cards

- On demand labels

Materials

- Cartonboard

- Plastics

- Paper

- PSA

Capabilities

- Cutting

- Etching

- Kiss-cutting

- Creasing

- Perforating

- Scoring

Features & Benefits

Continuous workflow.

Accepts digital files and coordinates laser operation and automation.

Provides uniform processing independent of cut shape and processing speeds.

Precise laser control for etching, kiss cutting or scoring.

Reduces set-up time; consistent production from operator to operator.

Will accept sheet loaders, unloaders and robotic pick-n-place.

Single or dual cameras for X-Y-Ø positioning of the cut pattern to printing.

Process speed is adjusted based on geometry.

Process up to 500 mm (20 in) width and in nite length.

Accepts a second laser for increased production.

The FlexStar system is available in multiple con gurations to fit your needs.

[PLACEHOLDER] Technical Parameters

| Model | LB3100 | LB3200 |

|---|---|---|

| System Footprint | Width: 3.2 m (10.5 ft) | Width: 2.3 m (10.5 ft) |

| Depth: 1.85 m (73 in) | Depth: 2.16 m (85 in) | |

| Height: 2.18 m (86 in) | Height: 2.18 m (86 in) | |

| Laser Power | -- Watts (Other laser sizes available per request) | |

| Power Requirements* | Controller & Chiller (Int) - 380-420 VAC, 3 PH, 50 Hz | |

| Controller & Chiller (US) - 200-230 VAC, 3 PH, 60 Hz | ||

The above data is subject to change. All speeds and hole sizes are dependent on laser power, material type and thickness, and process platform - consult with Preco, Inc.

* Laser Chiller may be powered separate or by laser system.

Have Questions? Contact Us